Quality Product at Reduced Operating CostsOur Anderson continuous dewatering and drying machinery and systems are the most versatile and efficient in the world for complete drying of rubber and polymers. We have been providing total finishing systems for over 60 years. The combination of Anderson Expeller® dewatering press and Expander-Dryer®, provides shortest time under temperature conditions known. This maximizes control, guaranteeing highest quality products, minimizes space requirements, reducing capital investment costs, and maximizes versatility in capacity and polymers dried.

Our experience from drying the range of rubbers and polymers processed today can be seen in our durable design and selection of metallurgy. This maximizes corrosion resistance, maximizes abrasion resistance, and minimizes operating costs related to wear parts overhaul Listing of synthetic rubber processed on our dewatering and/or drying machinery

|

|

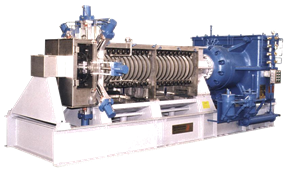

No 10A Expander-Dryer® |

|

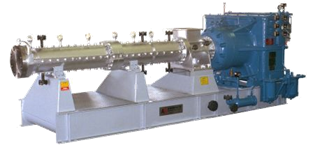

No. 7A Expeller® Press |

|

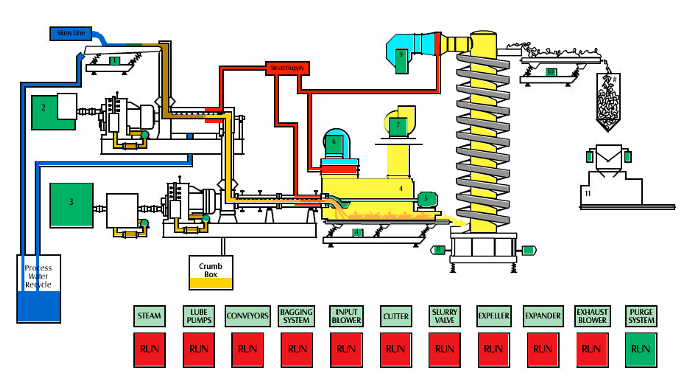

Programmable Logic Controller Panels

Designed to monitor and control the complete finishing line |

|

Dewatering

-Dewatering Screens -Skimmer Tanks -Expeller® Presses |

|

Drying

-Expander-Dryer Expanders® -Hot Boxes -Spiral Elevators |

|

Baling

-Baling Presses -Vibratory Feeders -Distributing Conveyors - Weigh scales |

|

Bale Handling

-Roller and Belt Conveyors -Metal Detectors -Check weighers -Line Reject Conveyors -Bale Wrappers -Bag Sewing Systems -Pallet Loading Systems |

|

Inventor of Advanced Processing Technology |

|

Dewatering and Drying Machinery |

|

With over a century of service, the mission of Anderson International is to create an environment whereby all who interact with us experience a time honored relationship built on |

|

· ABS |

· Polypropylene |

· Graft Copolymers |

|

· EPDM |

· Reclaim Rubber |

· Halobutyl |

|

· SBR (Emulsion and Solution) |

· Natural Rubber |

· Polychloroprene |

|

· BUTYL |

· Reclaim Films |

· Polyethylene |

|

· PBR |

· Fluoroelastomers |

· Polyisoprene |

|

· High Styrene SBR |

· TPE (SIS and SBS) |

· Carbon Black Masterbatch |

|

· Random Copolymers |

· PVC (Flexible) |

· NBR |

|

· Block Copolymers |

|

|